Glass Crushing Systems

Glass Crushing Systems

GB350/GB350T GLASS CRUSHERS

High-capacity crusher for bottles, ceramics, and plate glass. Reduces volume by 80%. Clean, quiet, and safe.

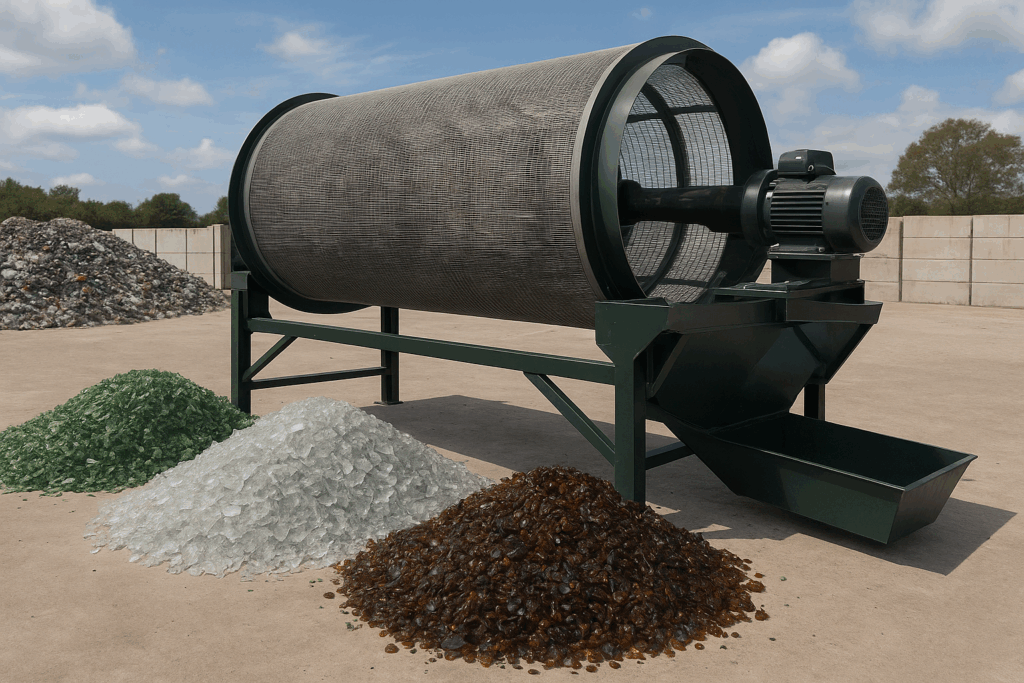

TROMMEL GLASS FILTER SYSTEMS

Rotating trommel for sorting crushed glass by size. Ideal for separating fine sand from larger cullet. Enhances recycling precision.

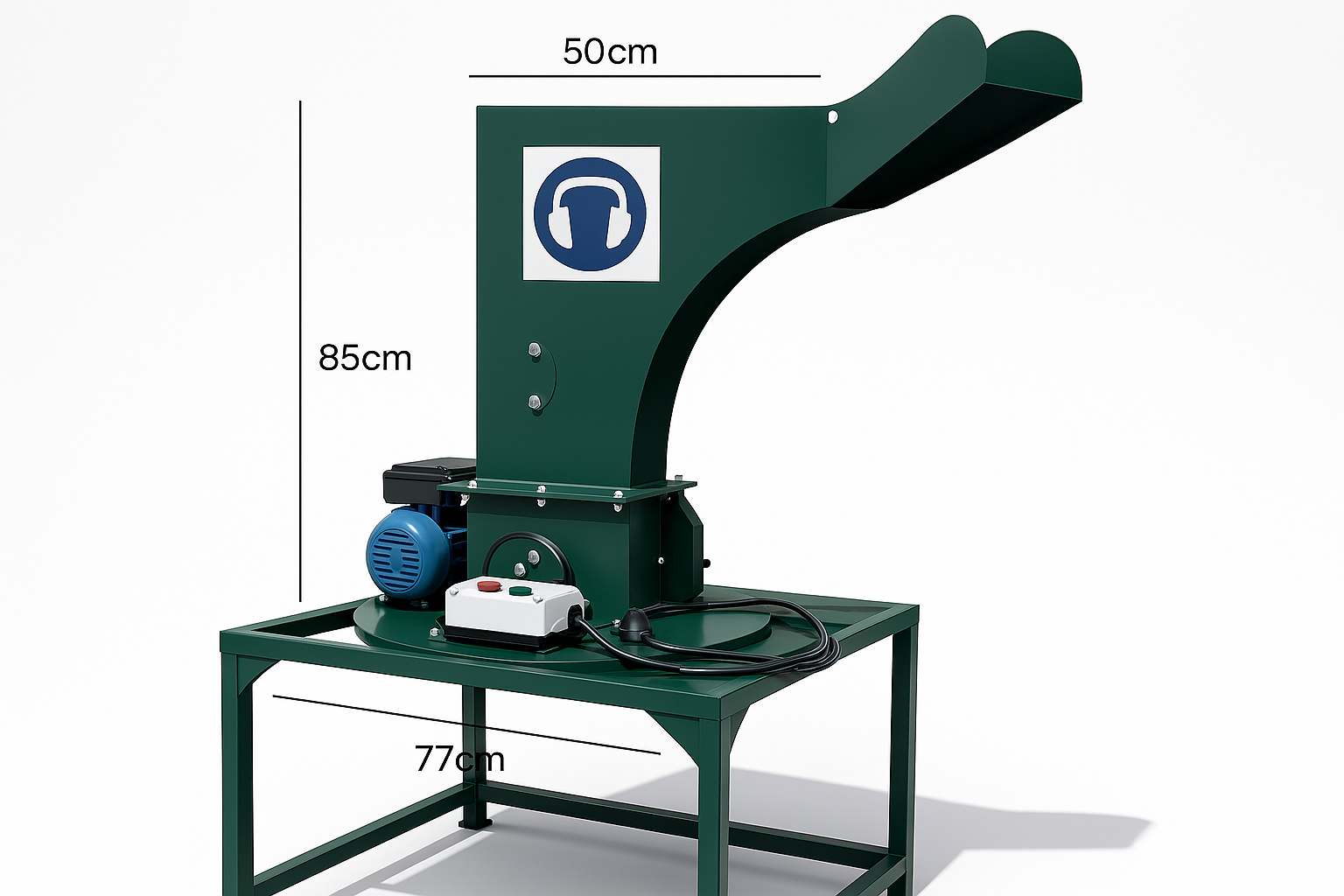

CR001 GLASS CRUSHERS

Drum-mounted crusher for bottles and ceramics. Produces fine glass sand. Quiet and compact.

GB150/ GB150T GLASS CRUSHERS

Compact crusher for small-scale glass recycling. Space-saving and efficient.

GB350T GLASS CRUSHERS + CONVEYER

Integrated crushing and conveying system. High-throughput and built for industrial use.

GLASS + BOTTLE CONVEYER SYSTEMS

Durable conveyor system designed for efficient glass loading. Built for integration with crushers to streamline operations.

Choose the Right size system for your requirements

- Built to fit your needs.

- From compact to industrial scale.

- Tailored for every operation.

- Scalable. Reliable. Efficient.

- Solutions for every size.

Why Recycle Your Glass?

♻️ 1. Reduced Waste Disposal Costs

Crushing glass on-site reduces the volume of waste, lowering transport and landfill fees.

🌍 2. Environmental Impact

Recycling glass helps businesses reduce their carbon footprint and contribute to a circular economy.

💰 3. Revenue Opportunities

Crushed glass can be sold or reused in construction, landscaping, or manufacturing — turning waste into value.

🏭 4. Operational Efficiency

On-site crushing streamlines waste handling, saving time and improving safety in industrial environments.

Trusted By

Some Of Our Clients

FAQ

1. What types of glass can your machines process?

Our systems handle all common glass types — bottles, jars, flat glass, and more.

2. Are your machines suitable for small businesses?

Yes, we offer scalable solutions from compact units to industrial-grade systems.

3. Can the crushed glass be reused or sold?

Absolutely. Crushed glass can be repurposed for construction, landscaping, or sold to recyclers.

4. Do your machines meet safety standards?

All equipment is designed with safety in mind and includes protective features and signage.

5. Is your equipment built for African conditions?

Yes — our machines are engineered to be robust, reliable, and suited to harsh environments.

6. Do you offer installation and training?

We provide full setup support and operator training to ensure smooth operation.

7. How energy-efficient are your systems?

Our machines are designed for low energy consumption without compromising performance.

8. Can I customize a system for my needs?

Yes — we tailor solutions to fit your specific volume, space, and operational requirements.

Ready to Crush Waste and Boost Efficiency?

Let us help you turn waste into value with systems built for performance and sustainability.