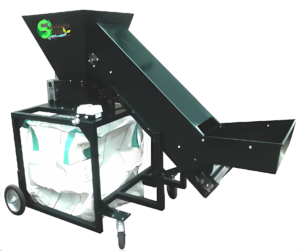

GB350 Glass Bottle Breaker & Conveyer

Crushes approximately 1300kgs of glass bottles per hour, reducing the bottles to a cullet 20-40mm. The volume of bottles is reduced by 80% i.e., 8 bags of bottles reduced to 1 bag of glass sand. Also crushes ceramics, pottery and plate glass (not laminated glass). Safety glasses, dust masks and gloves are essential for safe operation. Quiet, clean and safe operation.

Mounting: Unit with hooks for 1 ton flow bin bags fitted to catch broken glass. 1150cm

Materials: Main frame manufactured from mild steel GW300; Crushing head manufactured from ROQ – tuff AM700 high quality steel

Weight: 380kg

Power: 2.2 kw with a reduction gear box – 0.75kW with shaft mounted gear motor

Machine Dimensions: 1900mm, Length: 2600mm, Width: 1250mm

Conveyor Dimensions: 380mm wide, with 360mm wide 2 ply PVC belt, with 35mm cleats at 150 centre.

Equipment: 2 fixed castors and 2 lockable swivel castors

Power 380 volts power supply.

GB350T Glass Bottle Breaker

Crushes approximately 1300kgs of glass bottles per hour, reducing the bottles to a cullet 20-40mm. The volume of bottles is reduced by 80% i.e., 8 bags of bottles reduced to 1 bag of glass sand. Also crushes ceramics, pottery and plate glass (not laminated glass). Safety glasses, dust masks and gloves are essential for safe operation. Quiet, clean and safe operation.

The internal dimensions of the Bottle Breaker are 1900mm high and 1300 mm wide with a depth of 1 meter. The Bag will fit on a pallet for ease of changing over bags. We have excluded the Pallet Jack, pallets and bags.

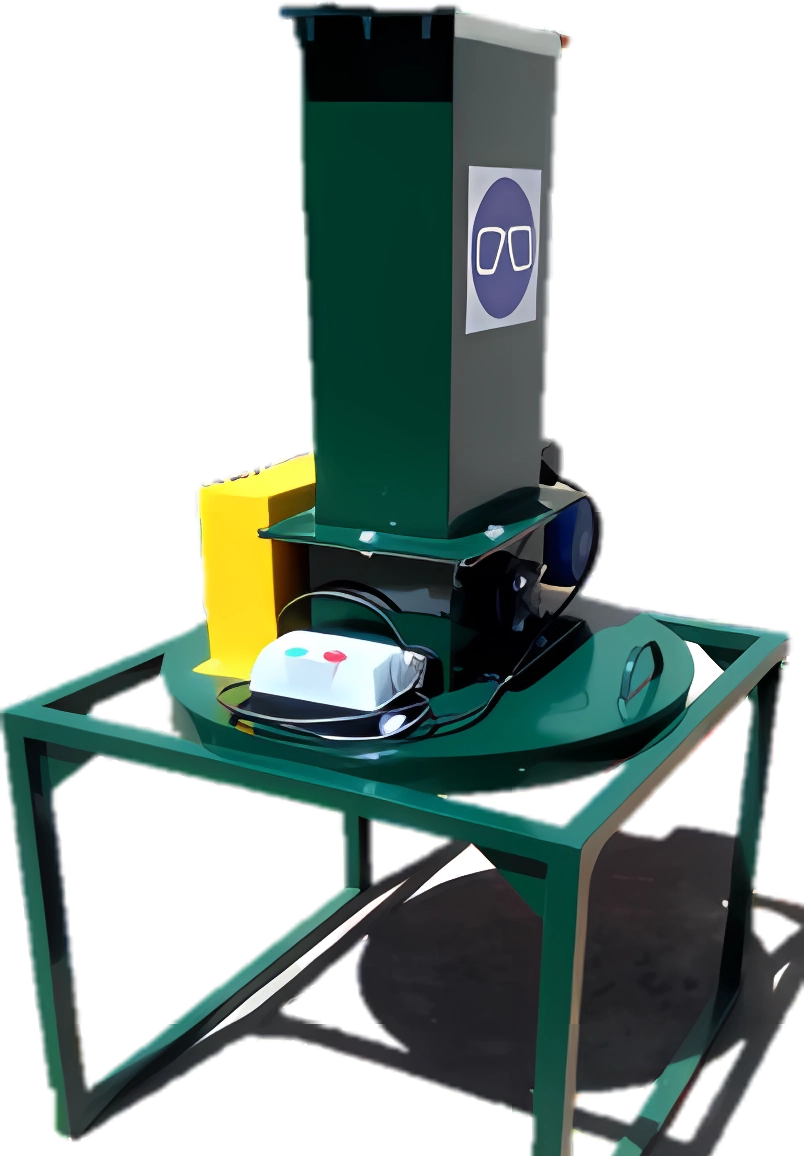

CR001 Glass Bottle Breaker

Crushes approximately 180kg of glass bottles per hour, reducing the bottles to non-hazardous glass sand. The volume of bottles is reduced by 80% i.e. 8 bags of bottles reduced to 1 bag of glass sand. Also crushes ceramics, pottery and plate glass (not laminated glass). Quiet, clean and safe operation. Crushed glass is less than 10 mm in diameter. Average grain size is approximately 4 mm.

Weight: 140kg Power: Single phase, 0.75 kW motor. Can be fitted with 3 phase if required.

Machine dimensions: 90cm X 90cm x 150cm Throat width: 500mm x 300mm

Function: The machine sits on a 210 liter drum or, when sitting on its stand, a No Hot Ash Drum that slides underneath the stand.

Control: Push button to start and stop.

TRAINING: Operation manual supplied.

MAINTENANCE: It is advised that a 6 monthly maintenance check should be carried out on all working parts.

Conveyer

The machine and conveyor are stand alone and not attached. The internal dimensions of the Bottle Breaker are 1900mm high and 1300 mm wide with a depth of 1 metre. The Bag will fit on a pallet for ease of changing over bags. We have excluded the Pallet Jack and pallets and bags.

Please note the the conveyor can not take broken glass or broken bottles this has to be put directly into the top of the Bottle Breaker.

The Power is 220 Volt as requested.

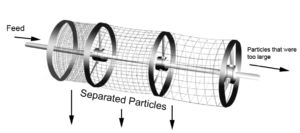

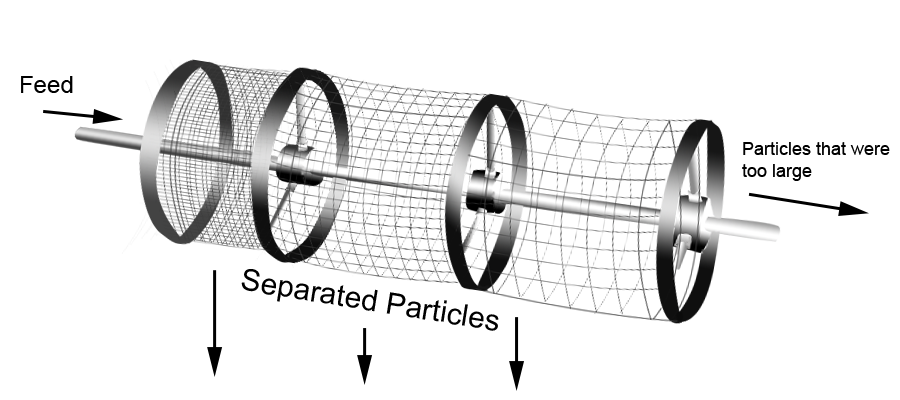

Trommel System

These systems are designed to specification requirements. such as required media size. These intended uses of the glass media and more. Please

We advice on a 6 months maintenance check on all systems provided.